Disgrifiad Cynnyrch

Prif Nodweddion:

1. J21 series Open Eccentric Presses is a general-purpose presses, suitable for forming, blanking, punching, bending and other cold stamping process.

2. C-ffrâm Castio fuselage, anhyblygrwydd mwyaf a gwyriad lleiaf ar gyfer rhannau cywir a bywyd offeryn hir. gall y corff gael ei ogwyddo, , anhyblygedd uchel a llai o anffurfiad Compact. Mae platiau trwchus a cholofnau mawr yn rhoi'r llwyfan sefydlog sydd ei angen arnoch ar gyfer eich cais heriol.

3. Mae'r Peiriant yn defnyddio dyrnaid bond cylchdroi anhyblyg anhyblyg ac wedi'i gefnogi'n dda. Mae'r cydiwr yn rhoi strôc parhaus ar gyfer cynhyrchu màs.

4. Mae siafft crank wedi'i wneud o ddur aloi arbennig wedi'i beiriannu i gywirdeb agos a'i osod mewn llwyni efydd ar gyfer gweithio'n llyfn, bywyd hirach a chywirdeb.

5. Properly sized flywheel, is made of high grade cast iron, for storing and releasing adequate energy for the pressing operations, and properly balanced for smooth running.

6. Mae gêr wedi'u castio neu wedi'u gwneud o ddur. Mae dannedd gêr yn cael eu cynhyrchu gan beiriant hobio manwl gywir.

7. Machine is with both hands button and foot switch control: anti-tie down, non-repeat controls with ring guards; conforms to OSHA.

8. Protective fence and the safety interlock to ensure the operation safety. Have a movable single-hand pedal switch,easy to operate.

Size Information

Manylebau | Uned | JH21-25 | JH21-45 | |||

Math | H | S | H | S | ||

Grym enwol | KN | 250 | 450 | |||

Strôc Enwol | mm | 3 | 3 | 4 | 4 | |

Strôc Sleid | mm | 50 | 80 | 70 | 120 | |

Slide Strokes Per Minute | Sefydlog | min- 1 | 125 | 100 | 95 | 80 |

Amrywiol | 75-150 | 60-120 | 65-115 | 50-95 | ||

Maximum Die Set Height | mm | 265 | 250 | 295 | 270 | |

Addasiad Uchder Die | mm | 50 | 60 | |||

Rhwng canolfan sleidiau a ffrâm | mm | 210 | 225 | |||

Columns Distance | mm | 450 | 515 | |||

Bottom size of slide | L×R | mm | 360 | 400 | ||

F×B | mm | 250 | 340 | |||

Shank Hole Size | Dia | mm | 40 | 50 | ||

Depth | mm | 50 | 60 | |||

Bolster size | L×R | mm | 720 | 825 | ||

F×B | mm | 400 | 440 | |||

Blanking Hole Diameter | mm | 150 | 150 | |||

Trwch Atgyfnerthu | mm | 80 | 110 | |||

Bolster Surface Height | mm | 780 | 800 | |||

Overall Dimensions | F×B | mm | 1500 | 1585 | ||

L×R | mm | 945 | 1075 | |||

H | mm | 2120 | 2390 | |||

Distance Between Foundation Bolts | F×B | mm | 980 | 1075 | ||

L×R | mm | 690 | 760 | |||

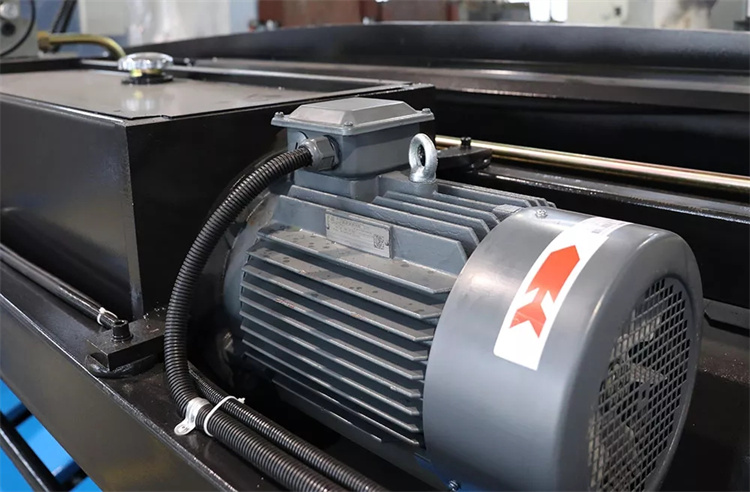

Modur | Pwer | Kw | 3 | 5.5 | ||

Weight(Approximate) | Kg | 2450 | 3550 | |||

Press Pressure | Mpa | 0.5 | 0.5 | 0.5 | 0.5 | |

Machine Details

Standard accessories: Optional accessories:

1) Wet clutch 1) Dry clutch

2) Hydraulic overload protecting pump 2) Pneumatic die cushion apparatus

3) Auto lubrication system 3) Light curtain

4) Manual lubrication system 4) Die quick change device

5) Hydraulic overload protecting pump 5) Foot pedal

6) Joint for miss-feeding 6) Automatic feeding the output shaft

7) Touch screen 7) Speed motor, frequency control

8) Electronic crankshaft angle indicator

9) Cam controller

10) Die height adjusted motor (JH21-100~400)

11) PLC: Programmable logical controller

12) Knock out device

13) Air source quick connector

14)Absorbing pads

15) Working lamp

16) Air blowing

17) Second degree drop

18) Preset counter